Dingsheng Group to share with you the latest industry news

In the SMT manufacturing process, tin powder has a decisive influence on the quality of SMT manufacturing.There are many factors that affect the manufacturing quality, such as the choice of metal particle size, the manufacturing process of the stencil,The opening design of the stencil, the flatness of the PCB, the setting of printing parameters, the characteristics of the solder paste itself, etc.So, how to choose the solder paste that suits you? How to choose the size of metal particles?

Solder paste can be divided into 6 types according to the size of metal particles, of which type 1 powder metal particle size is the largest, type 6 powder is the smallest (as shown in the table below). The spacing between PCB is large, and the size of the stencil opening is large, so a larger solder paste with metal particles. On the contrary, for fine-pitch component assembly, it is necessary to use solder paste with small particle size.In principle, in terms of cost and soldering quality, solder paste with large particle size has low cost, low oxidation probability, andIt has better application effect. Conversely, solder paste with smaller metal particles is more expensive and has a higher chance of oxidation.On the contrary, for a small stencil opening size, large particles of solder paste may cause poor printing and poor release propertiesHowever, small-sized metal particles can improve the release performance of solder paste, but printing collapse may occurquestion etc.

| Particle Type | Particle Size | Mesh Size | Application | ||

| Mils | Millimeters | Microns | |||

| Type 1 | 3.0-6.0 | 0.075-0.150 | 75-150 | -100/+200 | Standard Pitch |

| Type 2 | 1.8-3.0 | 0.045-0.075 | 45-75 | -200/+325 | Standard Pitch |

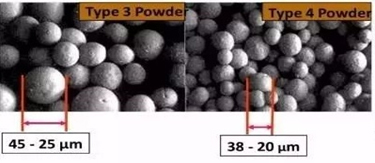

| Type 3 | 1.0-1.8 | 0.025-0.045 | 25-45 | -325/+500 | Fine Pitch |

| Type 4 | 0.8-1.52 | 0.025-0.038 | 20-38 | -400/+500 | Fine Pitch |

| Type 5 | 0.6-1.0 | 0.015-0.025 | 15-25 | -500/+635 | Ultra Fine Pitch |

| Type 6 | 0.2-0.6 | 0.005-0.015 | 5-15 | -635 | Solder Bumping |

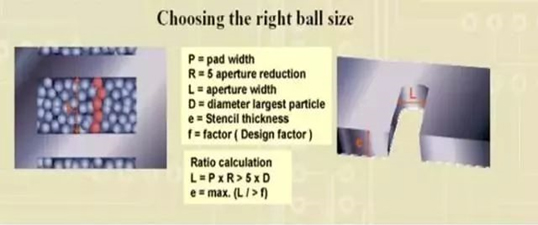

Therefore, it is particularly important to choose what type of solder paste, and how to choose it in actual production. For our own solder paste, we need to follow an important principle, that is, the "five ball rule", that is in at least five solder balls can be placed in the direction of the minimum size of the stencil opening or the PCB, and the diameter of the solder ball is determined by the model.Maximum size is a guideline. For example, for QFP components with a pitch of 0.4mm, the PCB width is generally 0.2mm, the maximum opening width of the stencil can only be 0.2mm, otherwise there will be process risks. If you choose type 3 powder, its gold the particle diameter range is 0.025—0.045mm, then the maximum solder ball diameter 0.045X5 is equal to 0.225mm, which is larger than the opening width of the stencil, and the type 4 solder paste has a diameter range of 20-38 microns, which is fullIt meets the requirements of the "five ball rule". Therefore, for 0.4mm QFP components, it is necessary to choose type 4 powder solder paste. It is not recommended to choose type 3 powder solder paste.

Five ball rule

Five ball rule