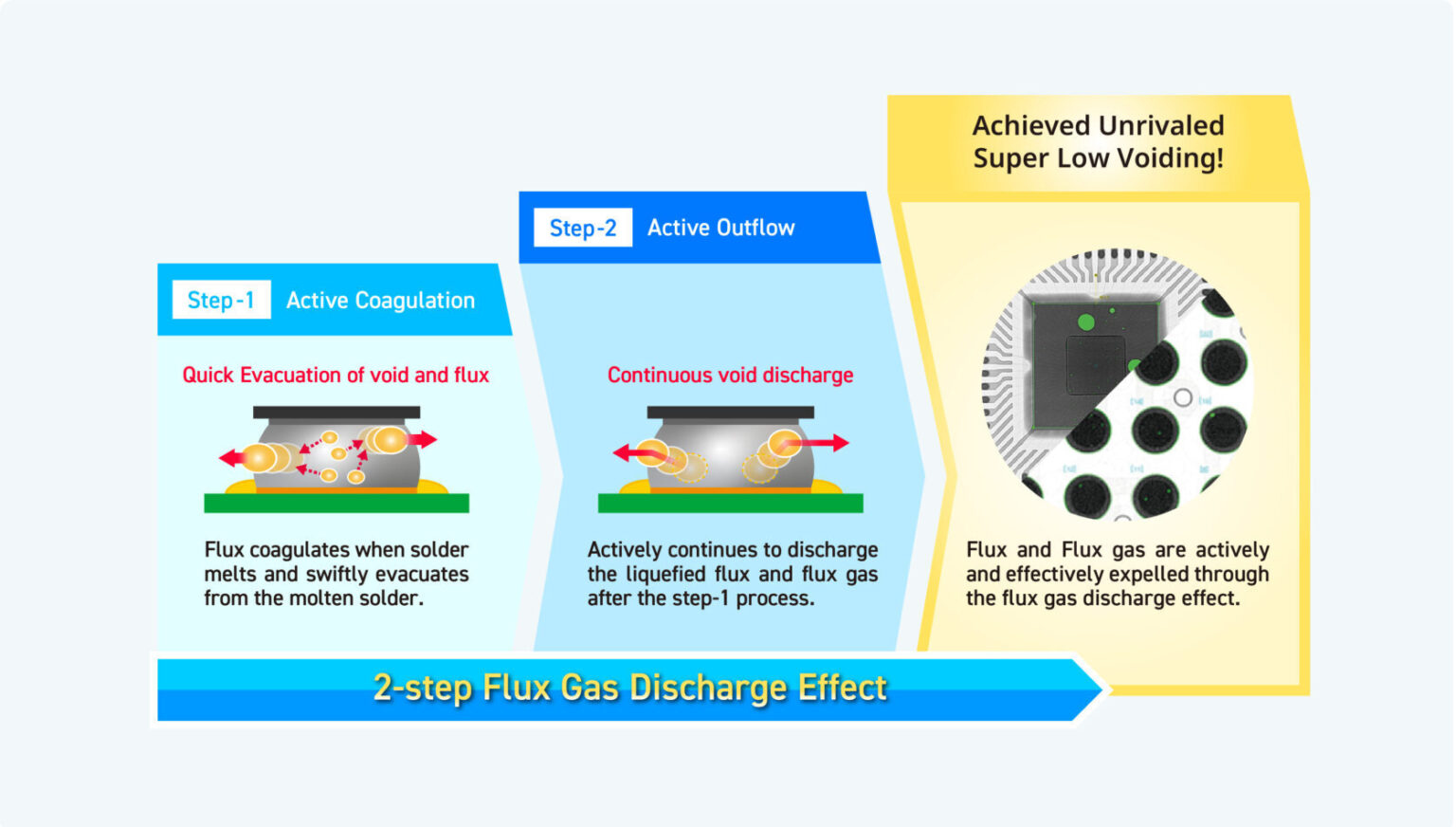

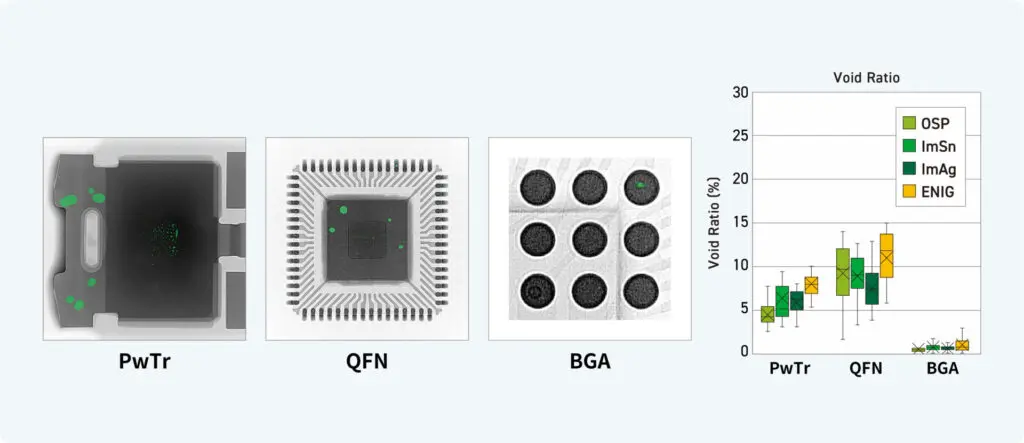

The S3X58-HF1200 provides a multifunctional solution designed to address major assembly challenges, including voiding, wettability, flux splattering, printability, electrical reliability, and halogen-free requirements. In particular, the ‘Dual 2-Step’ Enhancement technology ensures exceptional soldering performance - all within a single, advanced formulation.

Feature

● Provides a multifunctional solution suitable for large industrial fields, particularly meeting most of the requirements of the automotive industry

● Realizes low voiding regardless component desgin

● Powerful wetting as good as Halogen containing solder paste

● Exhibits excellent print quality, which may reduce stencil cleaning frequency

● Halogen free, no artificial addition of any halogen element