Dingsheng Group to share with you the latest industry news

2024-10-28 | Hits:947

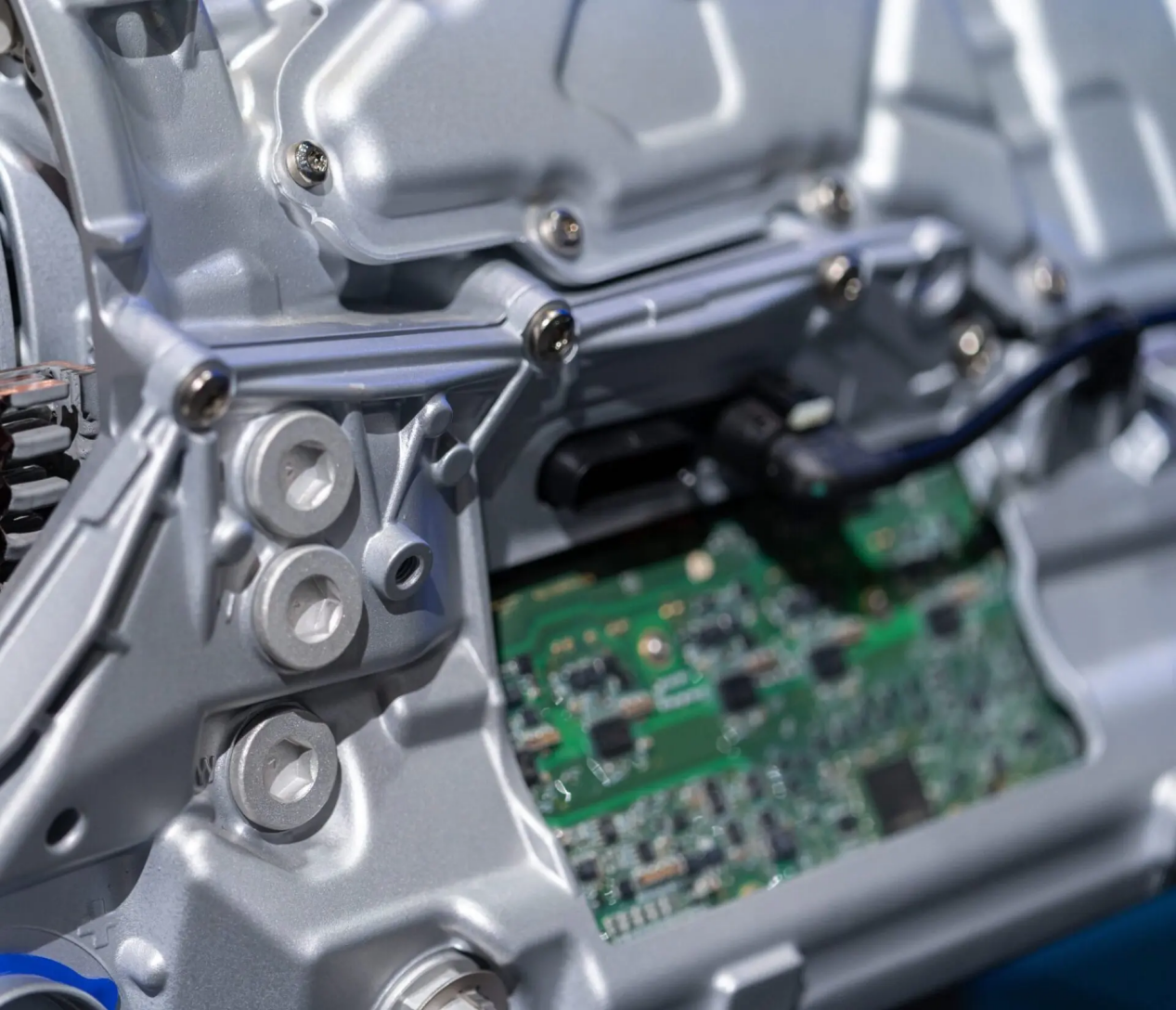

SB6NX is a high-reliability alloy that reduces solder joint transformation through advanced alloy strengthening technologies. The addition of indium significantly enhances the thermomechanical durability of the solder joints. With excellent thermal fatigue properties, SB6NX is ideal for harsh conditions, improving product life in automotive and industrial equipment. Additionally, its lower melting point compared to SAC305 allows for reduced reflow temperatures. It is applicable for any surface finishes of the PCB, including ENIG.

Feature

● Effectively suppresses crack extension under thermal cycle conditions

● SB6NX alloy is applicable for any surface finishes of the PCB, including ENIG

● Significantly reduces voiding

● Enables to use the same reflow profile as SAC305

● Complies with Halogen Free standard (BS EN14582, Br+Cl < 1,500 ppm)

Recommended for ENIG finish

In ENIG finish, Sn-Ni IMC layer thickens and along with concentration of P causes the joint interface brittle.By adding Ni-compatible Cu, SB6NX forms a Ni barrier layer and effectively prevents the thickening of Sn-Ni IMC layer, realizing high joint reliability with ENIG finish.

For the better joint reliability

In comparison with SAC305, SB6NX has better elongation property and is less prone to deformation. That helps to prevent propagation of crack at the solder joint in thermal cycling. As found below, SB6NX shows much higher sheer strength than SAC305 with ENIG and OSP substrate alike.